General

- NO convertibles, limos, hearts, compacts, 1973 and older imperials, pickups, or panel trucks or sedagons allowed.

- All glass, rear seat, interior panels, and exterior hardware must be removed. (i.e. door handles, chrome molding, lights)

- Seat belts are mandatory. A reg signal flag will be required in the car along with the stick on the column

- Driver’s door and post must be padded sufficiently to protect the driver. (Only one driver per vehicle)

- Cars may be subject to re-inspection.

- Car numbers must be a minimum of 20” tall by 4” wide and visible on both sides and roof. (roof signs are ok)

- No obscene or risque sayings will be allowed on cars

- Air filter must remain on the engine at all times, no starting fluid allowed

- Brakes must function and demonstrate the ability to stop before and during the show.

Fuel Cell, Transmission Coolers, Battery

- All engine and transmission combinations are allowed. Must be mounted within 5” of stock mounts, a lower engine cradle may be used with a lower dampener protector.(No mid plates or distributor protectors) If using engine cradle, the cradle may only be welded or bolted to the crossmember.

- Gas tanks must be removed and a fuel cell or marine type tank must be mounted in the cab of the vehicle.

- If using marine type plastic cell, it must be barricaded from the driver with tin/metal.

- 7 gallon maximum fuel capacity.

- c. Fuel Cell must be behind the driver’s seat or in the center of the car where the back seat used to be. Must be securely mounted behind the driver’s seat to the sheet metal or you may suspend it on your cage, but the tank may not be attached to both. Fuel cell must be mounted with bolts, metal straps, or chain. Do not use seat belts or pull tie straps to secure fuel cell. Fuel cell may have protector around it but cannot be within 4” of ANY sheet metal.

- Batteries must be relocated to the cab of the vehicle and must be bolted down four ways.

- Battery must be covered.

- Transmission coolers are allowed and must be secured four ways.

- Water is the only engine coolant to be used, no antifreeze.

Body, Frame, Cage

- All body/frame parts must remain in original position. (cross members, trailing arms, core support)

- A minimum of two 10” holes must be cut in the hood. An 8” hole must be cut in the trunk lid.

- No altering front or rear suspension, components must remain stock EXCEPTIONS: Oem passenger car rear end swaps are allowed and front suspension may be welded solid with two 4”x4”x¼ plates per rail.

- No truck rear ends, no full float rear ends, no eight lug rear ends

- Rear end must mount in the footprint of the stock rear end that came out of the car

- Firewall, radiators and engine must remain as close to stock position as possible. Firewall may be split to accommodate engine/transmission combination but must be covered prior to passing inspection.

- 2 front and 2 rear 1” max. dia. all thread may be used for core support. May go through hood and frame, may go through trunk and frame. Maximum 4” washers allowed. 4 per all thread, may be welded to body, not to frame

- Drivers door must be reinforced. Reinforcement shall not extend more than 6” beyond front and rear seams.

- Wedging and pre bending will be allowed, 1980 and newer cars may cut, tilt, and weld frame back together, (one per frame rail) no filler metal, no plating.

- A 2”x2” min. – 4x4x¼” max. bar must be welded behind the driver’s seat and have a roll bar connected to it.

- The dash may be removed and a max. 4x4x¼” bar may be installed in its place.

- Two side bars may connect from dash bar to seat bar but must not extend past seat bar. (cage)

- No connecting cage to frame in any place.

- Ends plates must be used on dash and seat bar, Maximum 10”x10”x1/2”

- Hood, trunk and door seams must be secured by ONE of the following ways

- 6” pieces of angle iron with one ½” bolt per set. (3 per seam)

- ⅜” max. diameter chain looped over seams. (3 per seam)

- c. Welded along seams, seams may be fully welded, max filler material- ½ round stock or 2” x ¼” flat strap

- Two window bars/straps must be installed from roof to firewall (hood) and also from roof to speaker deck (trunk) .

- Window bars may extend 6” onto the hood and trunk lid

- Maximum 2”x2” tube, 2”x¼” flat strap, or 1” rebar/round stock

Bumpers

- Bumpers may be welded to bumper brackets and bumper brackets to the frame.

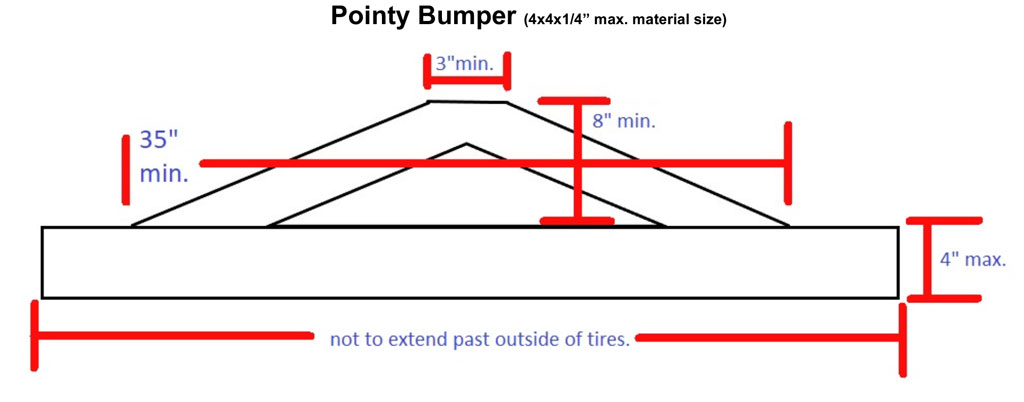

- Must run passenger style oem bumper, or ¼”x4x4 tubing, may be pointy but must meet min. requirements

- If running 4x4x1/4 tubing, original bumper brackets may still be used

- If bumper brackets are not used, you may use max. ¼”x3”x3”x14” tubing 1 per rail, front and rear

- Frame may not be cut more than 4” to accommodate mounting the bumper.

- No relocating or stuffing bumper shocks inside of the frame.

- If using ¼”3x3x14 tubing to mount, bumper shocks will not be allowed

- Bumpers must also be secured to the car with either a maximum of two – wraps of ⅜” chain or two ¼”x2” flat strap not longer than 36”. If using strap you may not weld more than the last 8” at either end

Aftermarket Parts, Components, wheels and tires

- Sliding driveshafts will be allowed.

- Slider steering shafts will be allowed

- Lower engine cradles with pulley protectors will be allowed

- Transmission braces will be allowed, must utilize stock bell housing, no steel bells, may not be attached anywhere different than stock mounting position, may not be pushed into the firewall, there must be a visible gap between transmission brace and sheet metal.

- Steel tailhousings will be allowed, may weld directly to crossmember.

- Aftermarket gas and brake pedal setup will be allowed.

- Electric fuel pumps may be used but must be brought to inspectors attention and have a toggle switch which is accessible and clearly marked for emergency shut off. If your car has fuel injection, you must use a stock wiring harness which shuts the fuel pump off when the car dies.

- Only stock oem wheels are allowed. Valve stem protectors allowed, 8” weld in bolt patterns will be allowed but not full centers,

- Any rubber tire, except solid rubber tires, may be used, only air may to be used for inflating tires.

- factory style OEM rear ends only, no eight lug read ends.

- Aftermarket axle shafts, posi, locker, yokes, and driveline brakes may be used..

- Body bolts may be replaced with ½x6” bolts, washers no larger than 2-½” may be used, must be mounted inside the frame, they may mount on top of floor and interior body panels. no pinning of frame with body bolts. Rubber mounts may be replaced with same size custom mounts, steel, hardened plastic, etc.

Pre-Ran Cars [These rules will also apply after heats]

- Pre-ran cars may be used.

- Frame may be restubbed but only to the firewall area with a butt weld, no filler

- Frames and body may be straightened and pulled out.

- Body may be patched with sheet metal for safety reasons, repairs shall be kept to a minimum.

- Frames of pre-ran cars may be plated.

- Repairs plates may only be used on damaged sections of frame, must be from previous heat or derby

- A total of 4 repair plates not to exceed 6x4x¼” may be used.

- Plates may be cut and manipulated but excess may not be used elsewhere

- Plates may not be welded to anything other than the frame. No bolting or pinning. No body to frame.

- Steering components may be repaired with 1x1x¼” angle iron.

For questions and clarification please call: Holden @ 435-469-0871